It is very strange that China even

have more strict environmental requirement on the dredging field than all over

the world, on the waste solids disposal and also the fluid dump, no matter

how it have been applied on field, in paper it is really advanced. So

basically when the oil market is down, we get a chance there, some client

in dredging field said. Just like you have done in drilling

waste management field. Also we have realised that not

only china all over the world, people are taking more care on the

environmental protection. For dredging, what we need is: Recycle the cleaner fluids.

Dump and reuse as much as possible on

the solids.

Not like the oil gas drilling, from the

pond, or from the river, from sea, there are sands, rocks, and other

things as you can imagine which have been buried in it. So

the separation seems very different. Except the basic concepts.

Separate the biggest particles and

other stuff other than the sands and silts. There are many ways to do this, one

is dig another pit / pond, with at big screen from where dredging pump

feeds, let the screen separate unreasonable parts to the pond, keep them away

from the progress. Another way is gumbo box, it is quite same as

the mining applications, to separate the biggest rocks from the first

step, then others feeding directly to the shale

shaker.

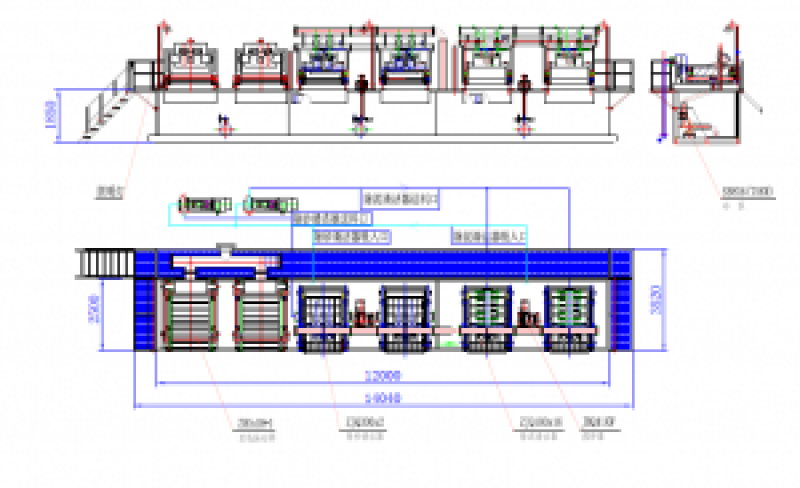

Then directly, or by another pump from the

pond. The feeding goes to the double deck shaker. In GN Solids Control , it is GNZS706E,

which is good to separate the bigger sands and the most of

the bigger solids. going through two sieves.

Catched by the pump, feeding to the

cyclones, to get the silts separated.

Then in the same way, separated by the

decanter centrifuge.

Sometimes it also need help from chemicals

that why a flocculent unit is there. To concentric the small particles

to be bigger ones, then easier to be separated.

Kindly contact GN for a full solution.