5 комплектов навесных грязевых цистерн для грузовиков проданы клиентам Саудовской Аравии на Ближнем Востоке

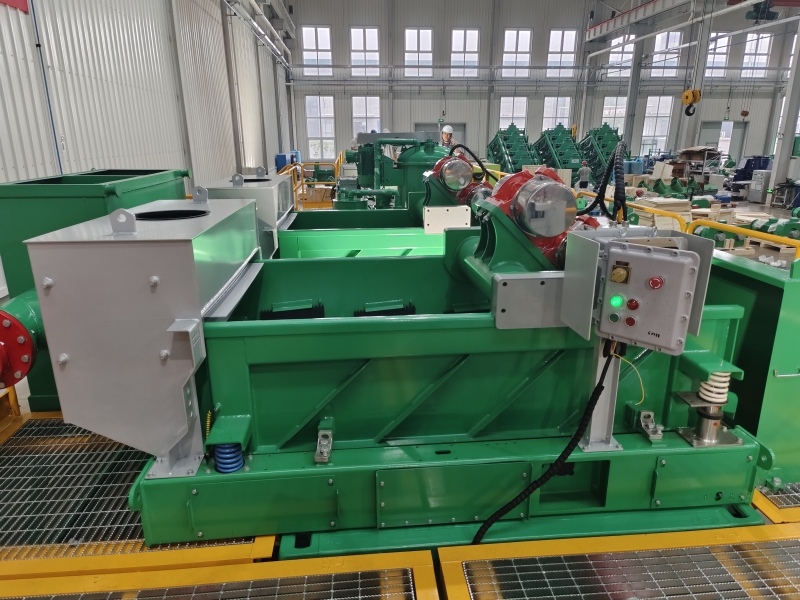

Ёмкость бурового раствора

GN Solids Control проектирует и изготовит вертикальные и горизонтальные ёмкости для бурового раствора, воды и масла по стандарту API & ISO. GN обычно используется гофрированными листами для сильнее боковой стены.

GN может изготовить разные емкости, включая емкость буровго растора, водянаяемко сть и маслянная емко сть и т.д. Обычно используется для установления оборудования, сохранения бурового раствора, приготовления бурового раствора и т.д. Сответствует ребованиями ЦС, станции бурового раствора, системы разделения. По разными условиями применения возможно изготовить вертикальную, горизонтальную и мобильную емкость на шассе.

GN Solids Control проектирует и изготовит вертикальные и горизонтальные ёмкости для бурового раствора, воды и масла по стандарту API & ISO. GN обычно используется гофрированными листами для сильнее боковой стены. Обычные горизонтальные ёмкости бурового раствора с установками блочного типа и трёмя проходов для удобного движения. GN обычно устанавливает ISO стандартные интерфейсы для удобного подъёма из верхней части ёмкости. Покрытие проходы, лестницы и смотровое отверстие оцинкованнами решётками. Для сталя GN Solids Control сначала занимается пескоструйной обработкой, что касается краски, GN использается Брендом Kansai Японии, толщина первого слоя 75μ, два раза работы эпоксидной смола, толщина 250μ, два раза отделочной краски полиуретана, толщина внешности ёмкости 75μ, по данным указанным красить два слоя во внутренности ёмкости.

Ёмкость бурового раствора — GN Solids Russia (gnsolidscontrol.ru)