You might become complacent that the machine is big monster having a large footprint and high weight. It always gets people to feel gloomy when standing before an enormous machine. But consider the following picture, how cute it’s. It’s a small decanter centrifuge from GN decanter centrifuge products. With small footprint, you can easily remove and transport, additionally, it saves a great deal space for customers. Regarding its parameter, the mainly two is dealing with capacity and speed. GN small decanter centrifuge’s dealing with capacity or processing volume is 6 cubic meter each hour. And it is speed can achieve to some maximum round each minute. As well as for its primary feature that we will talk in next paragraph, it is usually utilized in core drilling.

GN mini decanter centrifuge using the model GNLW223 mainly occupied the next features.

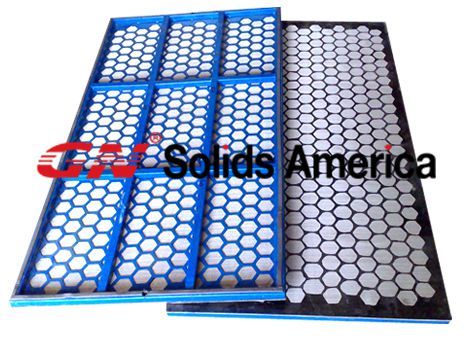

1. small footprint for simple moving and narrow working space

2. One motor driven mode for the bowl and inside screw propeller. The motor drive the bowl using a belt lever with devices, the bowl has same rotation speed because the motor. Meanwhile, the style of gear unit helps make the input speed from the screw propeller is a lot less than the bowl ¨C the screw propeller can also be driven through the motor having a belt lever. Thus the presence of the differential speed results in the centrifuge working availability.

3. High typical accelerate to 4500 make the sufficient G pressure to split up the fine solids with size 2~5 microns.

4. Material of SS304 on bowl, screw conveyor and primary body and protection of tungsten carbide squirting welding is perfect for lessen the cost, but could satisfy the working demand well.

5. Both fixed speed and variable speed model can be obtained

GN Solids Control has approached with lots of clients from Canada in the industry of core drilling along with other mining drilling. To think about our prime requirement around the motor and control panel explosion proof standard, GN provides the Small centrifuge only mechanical part and also the customer may find the motor and control panel in your area. And GN has done such as this before.

Related article:

http://gnsolidsamerica.nation2.com/index.php?page=1372521394_11