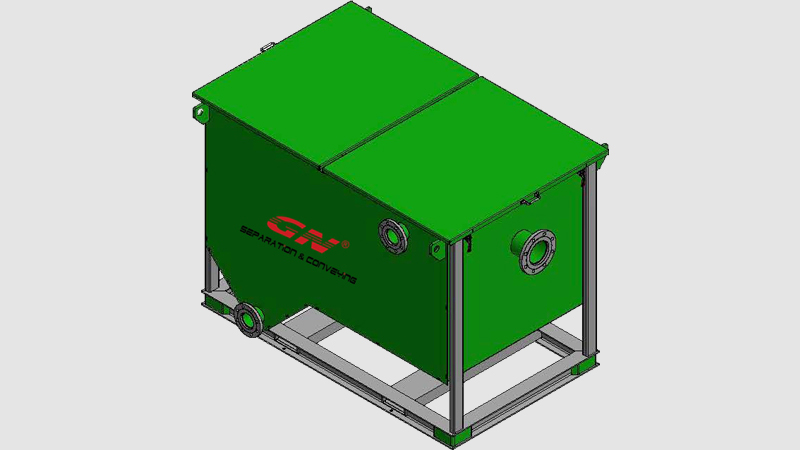

There is one set of drilling mud recycling system is under final assembling in GN Company‘s work plant, and would be ready for shipment soon.

This Drilling Mud Recycling System mainly includes equipment as follow,

Shale Shaker,

De-sander,

Pump, Pipeline, Accessories, etc.

The shale shaker is used to remove coarse solids, with size more than 100um.

The Desander is used to remove solids, with size 45~70um.

Working Procedure as below,

Feeding Drilling Mud to Shale Shaker through Mud Logging Tank, solids with size bigger than 100um would be shake out.

The drilling fluid passing through shaker screen would be pumped to Desander by Submersible Slurry Pump, solids with size 45~70um would be shake out.

The client also ordered one set of Jet Mud Mixer, including Mud Hopper, Mud Mixing Pump (centrifugal pump), for mixing the drilling fluid with chemical products, in order to improve its working performance.

GN Company is a professional manufacturer of Solids Control Equipment for 11 years, including Decanter Centrifuge, Shale Shaker, Shaker Screen, Desander/Desilter, Pump, etc.

GN Company supplies about 300 sets of decanter centrifuges in 2018, with 70% for International Market, including UK, Canada, Australia, USA, Russia, China, etc.

GN Company has two factories under operation, and a third one under manufacturing now, with more than 100, 000 square meters totally.

Welcome to contact GN Sales Managers for technical specifications and offers.

We would attend IFAT Exhibition in Germany, dated on May 4th~8th, 2020, with booth No. 104-b, Hall A1

Best & Regards,

Kevin Liu

Regional Manager

GN Separation & Conveying

Hebei GN Separation & Conveying Equipment Co.,Ltd

Tel:+86-316-5276988/9 Fax:+86-315-5276990

Mob(WhatsApp/Wechat): +86-15810901775

Email: kevin@gnseparation.com

Web: http://www.gnseparation.com

Address: No. 1 Zhongxun Road Dachang Chaobai River Industry Zone, Langfang, Hebei, China (Close to Beijing Int. Airport)