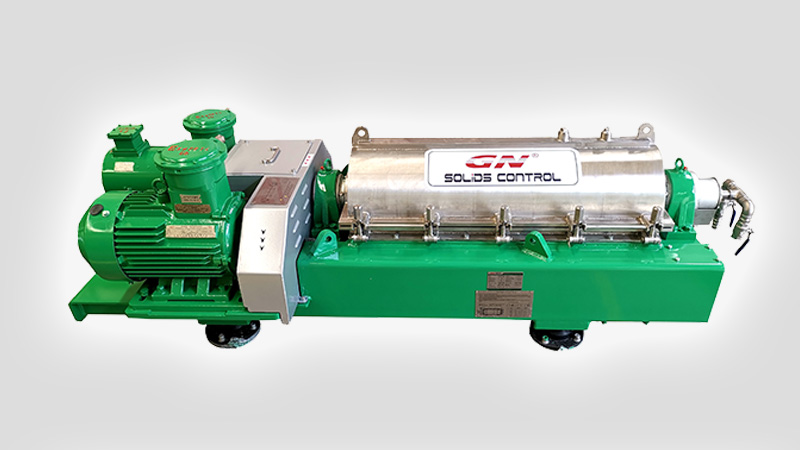

Since its beginnings, GN has designed, developed and produced different kinds of centrifuges for solid/liquid and liquid/liquid separation.

GN clarifying decanter centrifuge is C series decanter centrifuge with beach angle of 20 degree. It suits for material of small particle size, low density difference between solids and liquid, moderate viscosity, moderate concentration.

| Model | GNLW-224EC | GNLW-364EC | GNLW-454EC | GNLW-554EC | GNLW_654EC | GNLW-764EC | |

| Bowl Diameter | 220 mm (9 Inch) |

360 mm (14 Inch) |

450 mm (18 Inch) |

550 mm (22 Inch) |

650 mm (25.6 Inch) |

760 mm (30 Inch) |

|

| Bowl Length | 924 mm (36.4 Inch) |

1512 mm (59.5 Inch) |

1890 mm (74.5 Inch) |

2310 mm (91 Inch) |

2730 mm (82 Inch) |

3328 mm (131 Inch) |

|

| Bowl Speed | 5600 RPM | 4600 RPM | 4000 RPM | 3500 RPM | 3200 RPM | 2800 RPM | |

| Max G Force | 3863 G | 4265 G | 4032 G | 3773 G | 3670 G | 3336 G | |

| L/D Ration | 4.2 | 4.2 | 4.2 | 4.2 | 4.2 | 4.4 | |

| Main Motor | 11 KW | 22/30 KW | 37/45 KW | 55 KW | 90/110 KW | 110/132 KW | |

| Back Motor | 5.5 KW | 7.5 KW | 11/15/18.5 KW | 15/18.5 KW | 18.5/22/30KW | 22/30/37 KW | |

| Beach Angle | 20° | ||||||

| Drive Type | VFD+PLC+ HMI | ||||||

| Bowl Material | SUS2304(Duplex Stainless Steel)/ SUS2205(Duplex Stainless Steel) Centrifugal Casting | ||||||

| Screw Material | SUS2304(Duplex Stainless Steel)/SUS2205(Duplex Stainless Steel) | ||||||

| Remarks |

|

||||||

| The above specification and parameters for reference only. | |||||||

The beach angle of the C series clarifying decanter centrifuge is 20 degree, so the bowl cone section is short, and the straight section of the bowl is longer, it will give the bowl to have a longer clarifying section.

The rotating part of these decanter tricanter centrifuges is mounted on a compact, in-line frame, with main bearings at both ends. Vibration dampers are placed under the frame. The rotating part is enclosed in a casing with a cover and a bottom section with integrated outlets for both solids and the liquid being removed.

Clarifying decanters are designed for the continuous separation of suspensions into solids and clarified liquid, it widely used for Food, Beverage, Edible Oil separation processing and transfer solutions .

For more information about GN Clarifying decanter centrifuge, please feel free to contact us at any time.