GN Solids control system involves the utilization of shale shaker, mud cleaner and decanter centrifuges to process drilling fluids and remove the expected solids prior to, during, and after the drilling operation. We mainly supplies three phases of solids control system including prior to drilling: mud mixing system, during drilling: mud reclaim system and after drilling: drilling cuttings waste management system.

GN is highly experienced in offering qualified solids control equipment for all types of drilling fluids in the world.

Prior to Drilling

Mud mixing system is applied for mixing all kinds of chemical to formulate the drilling fluids. Generally, we apply the centrifugal pump, venturi hopper even shear pump for circulating and mixing drilling mud. The capacity of centrifugal pump ranges from 200GPM to 1408 GPM. Shear pump is capable of reducing the cost of mixing polymers an clays while improve the mud properties. Also, we utilize the mud agitator and mud gun to suspense solids prevent from sediment. Regarding to the customer’s requirement, we are able to customize the length of shaft of mud agitator and length of mud gun

During Drilling

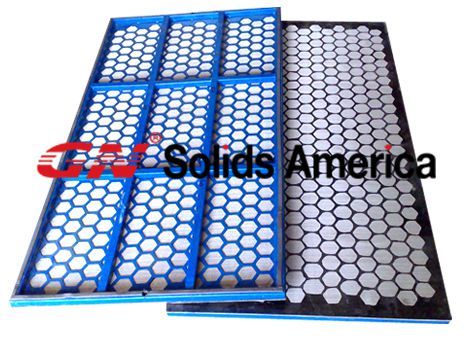

Solids Control equipment are capable of reclaiming the drilling fluids. Technically, we offer the series of equipment including shale shaker, desander, desilter the combination of desander cones and desitler cones and decanter centrifuge. The four steps of solids control equipment remove different size of solids in order keep the drilling fluids property

After Drilling

Drilling cuttings waste management system is use for processing the drilling cutting s during drilling and after drilling. Especially, drilling cuttings waste management system is for offshore project. When offshore project produce some drilling cuttings, contractor normally keep the cuttings and subsequently reclaim in the land. Therefore, our drilling cuttings waste management system is widely used for onshore and offshore drilling project. Our field experienced technician staff will work to assure that every project has a solution optimized for the drilling cutting being disposed.

GN is waiting for working with your project. Click this link, you can make a connection with us: http://www.gnsolidsamerica.com/contact.html