Although the oil and gas industry makes many oil

and gas pertaining companies to feel sad in the past year by the low price from

the crude oil, there are still likelihood for the good companies. Including GN

Solids Control, their own clients are still buying. The particular drilling

companies in South africa are still looking forward to a better future to come

by fully organized for equipments and staff members.

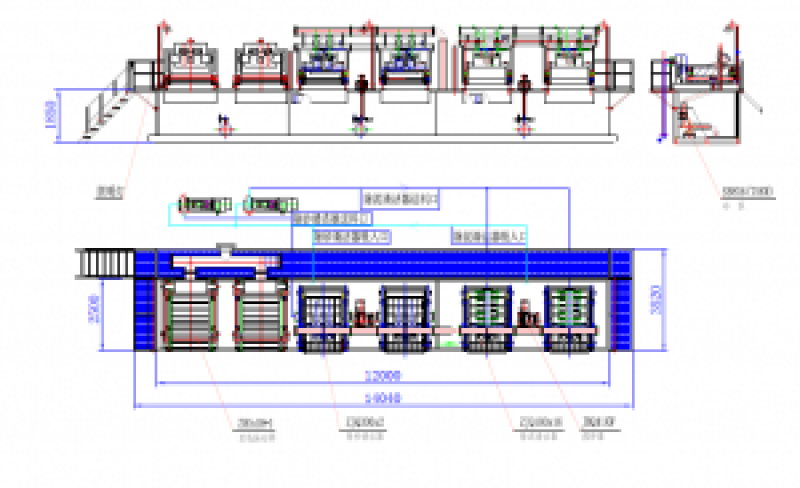

This time, GN Solids Control sent engineers to a Upper Africa company on

request with the client to do the having of 1 set of mud flower and 4 sets

connected with waste management systems.

That is a large drilling company with Africa which provides solids control and waste

management equipment and services to the essential oil companies who have

oil job areas in Africa. They use workers from local South africa while

importing equipments via all over the world. Before, they acquired equipment

from USA simply, but in case of the lower oil price, in order to get some sort

of squeezed benefit to be much larger, they choose to find vendors from China,

and they visited just about all main Chinese rig suppliers and solids control makers and finally

decide to buy from GN Solids Control.

Because:

one GN is most well known solids control manufacturer in China and taiwan and

also 1st API licensed in China.

2 . aside from API certifications, GN also obtained ISO, DNV CE, HSE and etc

certificates, exhibiting the responsibility of the company for the society and

environment.

a few. GN’s product including vertical cuttings dryer , shale shaker , shear pump , oilfield shale shaker , mud

cleaner , desander and

desilter , vacuum degasser , Mud Gas Separator

, decanter centrifuge , mud tank , mud agitator , etc .is the same as the US

and Europe providers, in another word, from GN, they can buy at a considerably

better price than US or maybe European suppliers but the high quality is

equivalent.

4. Reassured after sale service as well as spare parts, for main tools and

systems, GN give engineers for first time having and training for end user’s

operators for free for a single week.

Regarding spare parts, GN usually have necessary spare parts in commodity for

quick delivery.

That is why more and more drilling corporations and oil service global

businesses are choosing to cooperate along with GN Solids Control.