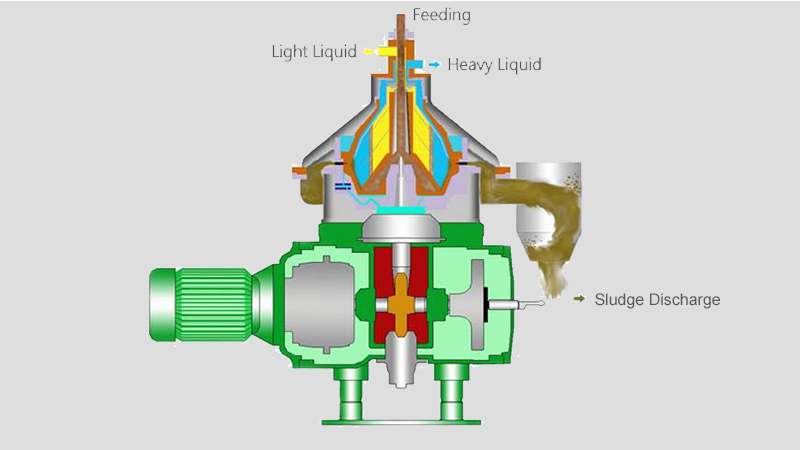

Disc stack separator is a kind of vertical centrifuge, The drum is installed on the upper end of the vertical shaft, and is driven by motor through the transmission device to rotate at high speed. Inside the drum there is a set of disc-shaped parts which are overlapped with each other, And the inner drum is a set of disc-shaped parts, which are nested and folded together. There is a small gap between the discs. The suspension is added to the drum by the feed pipe at the center of the drum. When the suspension flows through the gap between the discs, the solid particles or droplets settle on the discs under the action of the centrifuge to form sediment or liquid layer. The sediment slides along the surface of the disc and separates from the disc and accumulates in the place with the largest inner diameter of the drum. The separated liquid is discharged from the outlet of the drum. The function of the disc is to shorten the settling distance of solid particles or droplets and expand the settling area of the drum. The disc installed in the drum greatly improves the production capacity of the separator. The solid accumulated in the drum shall be removed manually after the separator is shut down, or discharged from the drum without shut down through the slag removal mechanism.

We GN separation company provide 2 phase disc stack separator (Liquid solid separation, separation of bottom concentration suspension, which is called clarification operation). and 3 phase disc stack separtor(Liquid-liquid separation or liquid-liquid-solid separation, the separation of emulsion is called separation operation )