GN solids America has

a used 14inch

bowl decanter centrifuge for sale in our

Houston warehouse, the address is 6710 windfern road, Houston, TX 77040,

welcome to drop by our warehouse and check it.

The specification of

the centrifuge is as below:

Decanter centrifuge

bow diameter: 14 inch

Bowl length: 50 inch

Effective treating

capacity: 132gpm at drilling fluids, but the treating capacity will varies at

different density & viscosity drilling fluids

Max bowl speed

3900rpm and normal working bowl speed is 3200rpm

The separation cut

point is 2~5 microns

Max G force up to

3063.

The electrical

control panel is IEC explosion proof standard which comply with US oilfield

standard.

The centrifuge is for

3 month rental only, now we will sell it with good discount, welcome to contact

our sales for price offer.

Features of the

centrifuge:

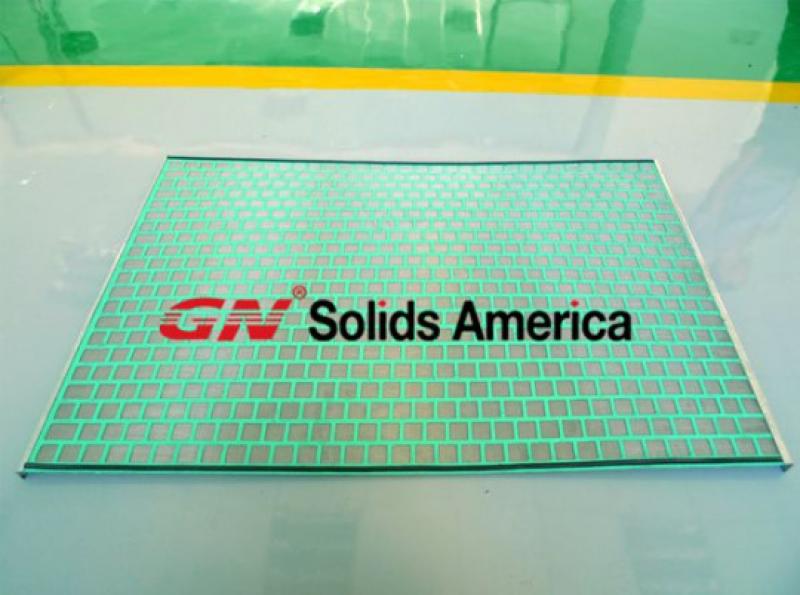

1 bowl material made

of duplex stainless steel 2205 and the other parts are made of SS316L

2

Screw conveyor is protected by tungsten carbide tiles

3 Screw flow

distribution port is protected by tungsten alloy

4 SKF bearing for

longer service life

Application of GN

stocked centrifuge:

1 Solids control

system, low gravity solids

2 Drilling cuttings

waste management, worked together with GNCD930

vertical cuttings dryer

3 Waste water

treatment

4 dewatering system

GN can provide low

speed pulley to use it for high gravity solids and barite recovery. We can also

provide telescopic skid to put the centrifuge on for convenient operation, the

feeding pump is optional.

We have another 3

sets of same model centrifuges for rent in the States, the specification is

equivalent to Derrick DE1000 / Swaco 518 / NOV Brandt

HS3400. We will show GNLW363 series decanter centrifuge at OTC

2015 oil show,we have 2 stands at

OTC, welcome to visit our booth at:

Reliant Arena Booth A

(290SF) No.: 9225-2 – Hebei GN Solids Control Co.,Ltd

Reliant Arena Booth B (200SF) No.: 6137 –

GN Solids America LLC

Related Arciels:

- GN Skid Mud System

- Oil Sludge separation equipment

- GNLW452 Decanter Centrifuge Special for Barite Recovery

- Desilter for drilling mud

- Drilling mud tank design concepts