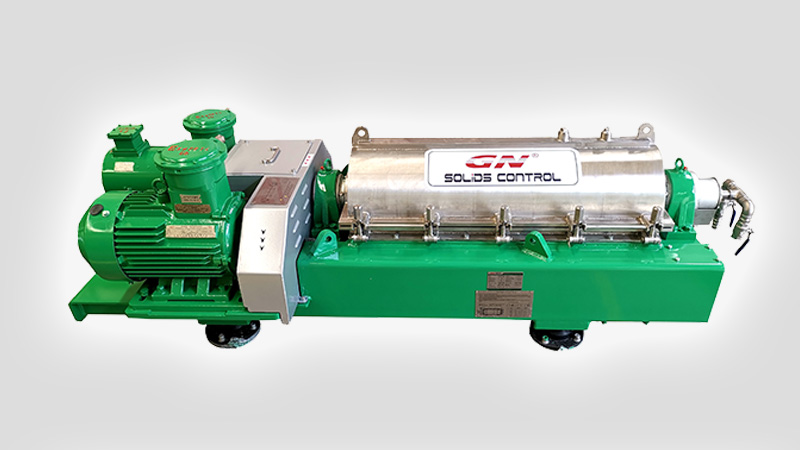

GN has designed, developed and produced different kinds of centrifuges for solid/liquid and liquid/liquid separation.

GN clarifying decanter centrifuge is C series decanter centrifuge with beach angle of 20 degree. It suits for material of small particle size, low density difference between solids and liquid, moderate viscosity, moderate concentration.

The smallest model is 224FT which is come with 220MM Bowl Diameter and the max G force is 3200G, The beach angle of the C series clarifying decanter centrifuge is 20 degree, so the bowl cone section is short, and the straight section of the bowl is longer, it will give the bowl to have a longer clarifying section.

GN can not only provide users with high-tech Clarifying Decanter Centrifuge, but also provide users with Clarifying Disc Separator with high rotating speed and G force is up to 12000 G, which can carry out multi-step clarification treatment for users’ materials, so as to achieve the most desired effect for customers.

For more information on 3-phase decanter centrifuge package, please feel free to contact GN Separation.

We have 3 models GNSP-40B, GNSP-20B and GNSP-10B, The maximum transport capacity of the three models for clean water is 10 cubic meters, 20 cubic meters and 40 cubic meters respectively. According to different material conditions, suction and discharge height and distance, the conveying capacity will be different. Generally, the lower the material density, the lower the viscosity and the shorter the conveying distance, the higher the working efficiency of the equipment will be.

We have 3 models GNSP-40B, GNSP-20B and GNSP-10B, The maximum transport capacity of the three models for clean water is 10 cubic meters, 20 cubic meters and 40 cubic meters respectively. According to different material conditions, suction and discharge height and distance, the conveying capacity will be different. Generally, the lower the material density, the lower the viscosity and the shorter the conveying distance, the higher the working efficiency of the equipment will be.