Recently, GN has completed 3 sets GNLW364 dewatering centrifuges for overseas municipal sewage treatment project.

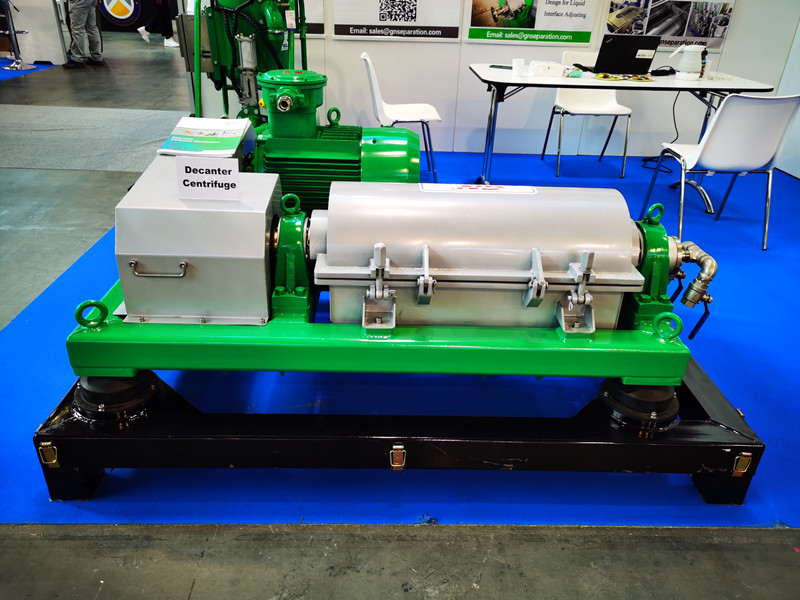

The GNLW364 dewatering centrifuge is a high-efficiency dewatering equipment produced by a well-known environmental pollution control equipment manufacturer in China. The equipment is widely applied in municipal sewage treatment projects, capable of effectively removing solid waste and pollutants from sewage, thus improving the efficiency and water quality of sewage treatment.

For an overseas municipal sewage treatment project, the configuration of three GNLW364 dewatering centrifuges can meet the project’s dewatering requirements. The equipment features:

High-efficiency dewatering: The GNLW364 dewatering centrifuge adopts advanced centrifugal technology, capable of rapidly removing solid waste and pollutants from sewage, thus improving the efficiency of sewage treatment.

Reliable operation: The equipment has a robust structure and reliable operating system, enabling long-term continuous operation to meet the needs of sewage treatment projects.

Easy maintenance: The design of the GNLW364 dewatering centrifuge considers maintenance and repair needs, featuring easy maintenance and repair, reducing maintenance costs and time.

Environmentally friendly: The equipment complies with environmental protection requirements, reducing the emission of pollutants and protecting the environment and ecosystem.

In summary, the configuration of three GNLW364 dewatering centrifuges can meet the dewatering requirements of overseas municipal sewage treatment projects, improving the efficiency and water quality of sewage treatment, and protecting the environment and ecosystem.

For More information, pls feel free to contact us.